Tank Manufacturing

Production of eliptical headed cylindrical tanks that can be installed above or underground ( with nominal capacities of 1 m3 – 150 m3 ).

Tank refurbishment and frame reinforcement

An economical, safe, environmentally friendly process for the renovation and frame reinforcement of hazardous liquid storage tanks using special PLASTIMOL®coating material.

Tank Inspections

Inspecting tanks required by regulations. Structural tests of underground and above-ground steel tanks in accordance with Hungarian official regulations.

Upgrade of single-walled tanks into double-walled tanks

With the application of reinforced plastic based coating system which contains the special coating material PLASTIMOL® developed by our company.

Corrosion protection

External corrosion protection and fuel side corrosion protection of underground tanks and storage tanks using a PLASTIMOL® plastic based coating system.

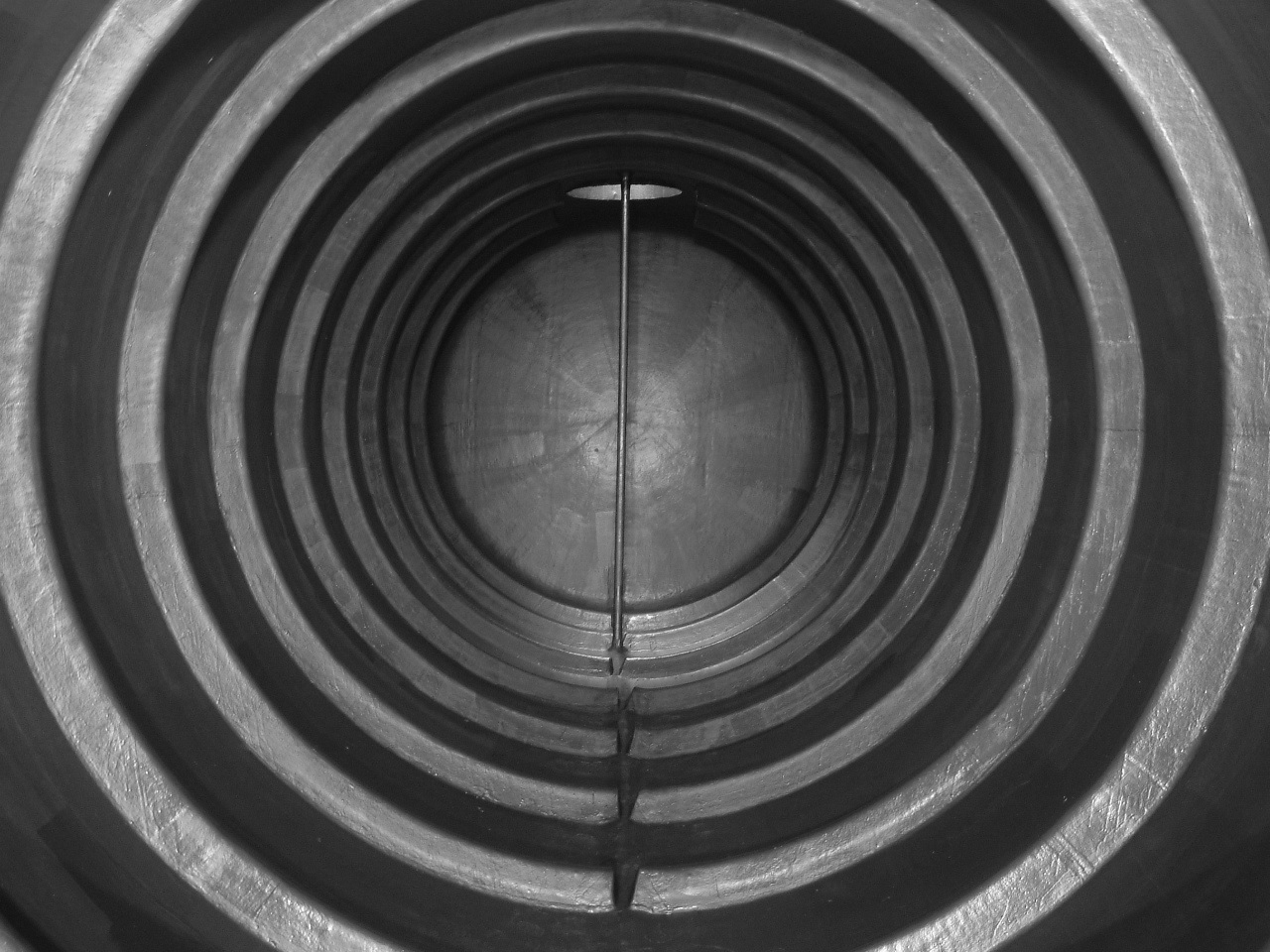

Manufacturing and reinforcement of tank lids

Reinforcement of the lid of a stationary cylinder with a composite coating, or replacement of the tank lid with a complete composite structure.

Leak testing

Vacuum deterioration compactness test, compactness testing and fault finding by means of helium pilot gas.

Conversion of tanks

Dividing tanks into compartments by installing a dome neck and creating a liquid-tight caisson shaft in one technological step.

Pipeline reconstruction and repair

Repair of large-diameter, pressurized industrial-technological pipelines with the usage of PLASTIMOL® bandage.

Authentication

Tank authentication and full administration.

Coating and repair of rescue basins

Coating and repair of rescue basins with usage of PLASTIMOL® plastic based coating system.

Manufacturing of custom composite elements

Fullfilment of special orders, implementation of individual composite elements.